News

18

2024

-

12

SPC flooring construction techniques and steps

Author:

SPC flooring (Stone Plastic Composite Flooring) is a new type of composite material flooring that features waterproof, moisture-proof, wear-resistant, and easy-to-clean characteristics, widely used in homes, commercial, and industrial places. This article will detail the construction techniques and steps for SPC flooring to ensure the quality and effect of the flooring installation.

I. Preparation Before Construction

Before construction, it is essential to make adequate preparations, which is the foundation for ensuring the smooth installation of the flooring.

1. Check the Flatness of the Subfloor

Checking the flatness of the subfloor is an essential step. SPC flooring has very high requirements for subfloor flatness, whether in new home renovations or old floor refurbishments, the ground must be flat without depressions or protrusions. In new home renovations, self-leveling treatment is a necessary step; while in old floor refurbishments, the height difference of the ground should be controlled within 2 millimeters to ensure there are no depressions or protrusions.

2. Ground Pre-treatment

Use a professional grinding machine to lightly grind the ground, removing residues and small protrusions to ensure the flatness of the ground meets installation requirements. After that, thoroughly clean the ground with a vacuum cleaner to avoid dust affecting the adhesive bonding effect.

3. Prepare Tools and Materials

Before installing SPC flooring, the following tools and materials need to be prepared: SPC flooring, cutting tools (such as cutting knives, cutting machines), straightedge, rubber mallet, filler (if needed), cleaning tools and materials (such as vacuum cleaner, mop, cleaning agents, etc.).

II. Laying the Moisture Barrier

Although SPC flooring itself has good waterproof and moisture-proof properties, laying a moisture barrier is still an important step. The moisture barrier can effectively isolate ground moisture, protecting the flooring from moisture erosion and extending its service life. At the same time, the moisture barrier can also act as a buffer, allowing the flooring to fit more closely with the foundation, providing users with a more comfortable foot feel.

1. Lay the Moisture Barrier

Evenly lay a layer of moisture barrier on the ground, securing it with tape or special clips to ensure the moisture barrier fits tightly with the ground without omissions.

2. Precautions

The thickness of the moisture barrier should be controlled between 1-2 millimeters; being too thick or too thin may affect the flooring's performance. Additionally, the moisture barriers should be aligned without overlapping, and the joints should be sealed with waterproof adhesive tape.

III. Flooring Installation

Flooring installation is the core part of the entire indoor renovation process, and its quality and effect directly relate to the overall aesthetics and comfort of the home. Therefore, it must be strictly carried out according to design requirements. Before flooring installation, the construction personnel need to thoroughly clean and treat the ground, ensuring it is flat, dry, free of oil stains, and debris. At the same time, appropriate installation tools and materials, such as flooring adhesive and flooring nails, should be selected based on the material and installation method of the flooring. During the installation process, construction personnel need to maintain a high level of focus and patience, accurately measuring the dimensions and positions of each flooring piece according to the design drawings to ensure the flooring is installed neatly and beautifully. Additionally, attention should be paid to the gap treatment between the flooring to avoid deformation or cracking due to temperature or humidity changes.

national customer service hotline:

+86-18934373051

Website:en.liblun.com

E-mail:liblun@163.com

Address: No.18, Luoxia East Road, Danzao Town, Nanhai District, Foshan City

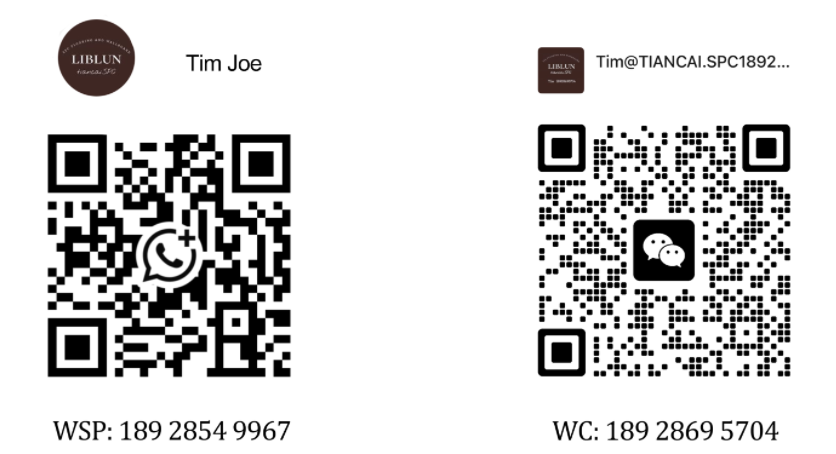

SPC Flooring. QR code

Copyright©Foshan Tiancai Environmental Protection Building Materials Technology Co., Ltd.