News

11

2024

-

12

Detailed explanation of the SPC wall panel production process

Author:

Detailed explanation of the SPC wall panel production process

SPC (Stone Plastic Composite) wall panels, also known as stone plastic panels or stone crystal panels, are a new type of decorative building material that combines many advantages such as fire resistance, environmental protection, waterproofing, moisture resistance, and scratch resistance. They are mainly composed of stone powder and polymer resin, with a board thickness typically ranging from 4 to 8 millimeters, and common specifications include 600*2440 mm, 1200*2440 mm, etc. It not only addresses many issues present in traditional decoration materials but also provides more diversified and higher quality options for modern decoration. This article will detail the production process of SPC wall panels.

1. Raw material preparation and mixing

The production of SPC wall panels first requires the preparation of basic raw materials. These materials mainly include stone powder, resin materials, and other additives. According to the formula ratio, various raw materials need to be accurately weighed using automatic measuring equipment to ensure stable product quality.

The weighed raw materials enter a high-speed mixer for hot mixing. The hot mixing temperature is usually between 120 and 130 degrees Celsius. The main purpose of this process is to ensure that the various raw materials are mixed evenly and to remove moisture from the materials. After hot mixing, the materials enter the cold mixing stage, where the cold mixing temperature is generally between 50 and 60 degrees Celsius to prevent material clumping and discoloration. Through cooling, the uniformly mixed materials are prepared for the subsequent extrusion molding.

2. Extrusion molding

The uniformly mixed materials enter the extruder for molding. The extruder uses the rotation and shearing action of the screw to compress the materials into continuous sheets. Parameters such as temperature, pressure, and speed during the extrusion process need to be strictly controlled to ensure the uniformity and stability of the sheets.

The extruded sheets, after cooling and shaping, enter the traction device for continuous pulling. The speed of the traction device needs to match the extrusion speed of the extruder to ensure the continuity and flatness of the sheets.

3. Surface treatment

The extruded sheets need to undergo surface treatment to enhance their decorative and durable properties. Common surface treatment methods include UV inkjet printing, surface painting, or applying decorative paper.

UV inkjet printing technology can directly print various patterns and colors on the surface of the sheets, achieving personalized customization. Surface painting provides a protective film to the sheets through spraying or rolling, while also increasing their gloss and texture. Decorative paper is adhered to the surface of the sheets using adhesive, achieving a decorative effect.

4. Positioning cutting and packaging

The sheets that have undergone surface treatment enter the positioning cutting stage. Cutting equipment accurately positions and cuts the sheets into the required sizes and shapes. During the cutting process, cutting precision needs to be strictly controlled to ensure that the product's dimensions and shapes meet design requirements.

After cutting, the sheets need to be packaged. Packaging materials are usually selected to be moisture-proof and dust-proof to protect the sheets from damage during transportation and storage. The packaging process also requires quantity statistics and labeling for subsequent management and use.

5. Quality control and testing

In the production process of SPC wall panels, quality control and testing are key links to ensure product quality. From raw material preparation to finished product packaging, each link requires strict quality control and testing.

In the raw material preparation stage, quality inspection of various raw materials is needed to ensure they meet formula requirements. In the extrusion molding stage, real-time monitoring of the thickness, width, length, and other dimensions of the sheets is required to ensure the accuracy of product dimensions. In the surface treatment stage, quality testing of printed or painted patterns and colors is necessary to ensure they meet design requirements. In the positioning cutting stage, cutting precision needs to be inspected to ensure that the product's dimensions and shapes meet design requirements. Finally, an overall quality check is required before packaging the finished product to ensure product quality is qualified.

As a new type of decorative building material, SPC wall panels have many advantages. Their production process involves multiple stages, including raw material preparation and mixing, extrusion molding, surface treatment, positioning cutting and packaging, as well as quality control and testing. By strictly controlling each production link, the stability and reliability of SPC wall panel product quality can be ensured, meeting the diverse and high-quality needs of modern decoration.

national customer service hotline:

+86-18934373051

Website:en.liblun.com

E-mail:liblun@163.com

Address: No.18, Luoxia East Road, Danzao Town, Nanhai District, Foshan City

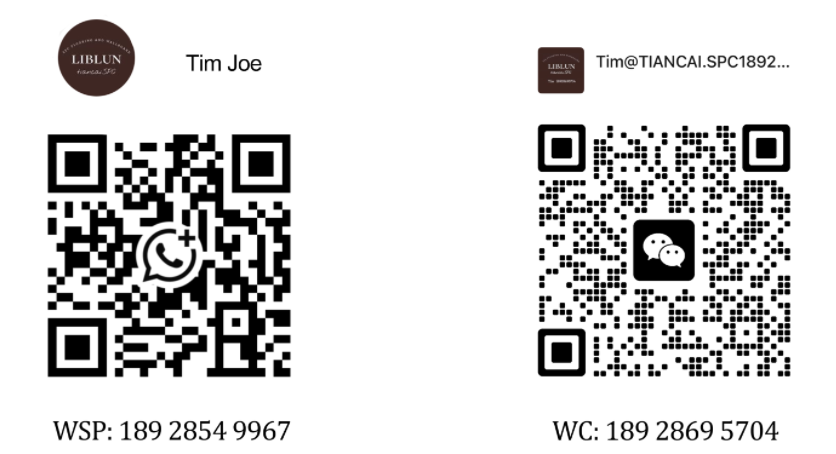

SPC Flooring. QR code

Copyright©Foshan Tiancai Environmental Protection Building Materials Technology Co., Ltd.