News

10

2024

-

12

The production process of SPC flooring

Author:

The production process of SPC flooring

SPC flooring, short for 'Stone Plastic Composite' flooring, also known as stone-plastic flooring, is a new type of flooring material that has gained popularity among wholesalers and consumers worldwide in recent years. It is made primarily from stone powder (mainly calcium powder or limestone powder) and polyvinyl chloride (PVC), mixed using high-tech processes. This article will detail the production process of SPC flooring, from the raw material ratio to the final product packaging, with each step being crucial.

1. Mixing

The production of SPC flooring begins with mixing. In this step, various materials are automatically measured and fed into a high-speed mixer for hot mixing according to the predetermined raw material ratio. The hot mixing temperature is usually set at 125°C, aiming to ensure uniform mixing of materials and eliminate moisture. After hot mixing, the material enters the cold mixing stage, where the temperature is generally around 55°C. This step further mixes the materials while cooling them down to prevent clumping and discoloration. Through cooling, the uniformly mixed materials can proceed to the next process.

2. Extrusion

After mixing, the material is sent to a twin-screw extruder for heating and extrusion. The extruder compresses the material into continuous sheets using high temperature and pressure. The sheets then enter a sheet die for shaping, and the formed sheets undergo thickness control through a four-roller calender. At this stage, the thickness of the substrate is precisely controlled to ensure the stability and durability of the flooring.

Once the thickness is set, the sheets proceed to the next step—applying a decorative film and a wear-resistant layer. The decorative film can be customized according to customer needs, mimicking the appearance of various natural materials, such as wood grain and stone grain. The wear-resistant layer is made from polymer materials and is bonded to the surface of the substrate through a special process to enhance the flooring's wear resistance. After bonding, the sheets are cooled, and then cut to form flooring products that meet specifications.

3. UV Curing

The cut flooring products enter the UV curing stage. UV treatment is performed to form a protective layer on the surface of the flooring, which has functions such as stain resistance, scratch resistance, and UV protection, safeguarding the surface from damage. The curing process involves alternating immersion in hot and cold water to release internal stress in the flooring, enhancing its stability and weather resistance. The temperature of the hot water during curing is typically between 80-120°C, while the cold water temperature is 10°C.

4. Cutting, Grooving, and Packaging

After UV curing, the flooring products undergo cutting and grooving. Cutting involves slicing the long strips of flooring to the required lengths, while grooving creates slots along the edges of the flooring for easier installation. After grooving, the flooring is also trimmed and beveled to improve installation convenience and aesthetics.

Inspection is a crucial step to ensure product quality. In this stage, each piece of flooring undergoes strict inspection to ensure it meets quality standards. Once passed, the flooring is packaged for transportation and storage. The packaging materials are typically moisture-proof and dust-proof to ensure the flooring is not damaged during transport.

5. Superior Performance and Applications of SPC Flooring

Due to its superior performance and diverse designs, SPC flooring is widely used in residential, commercial, and industrial environments. Its excellent stability and durability address the issues of moisture-induced deformation and rot found in solid wood flooring, while also avoiding harmful substances like formaldehyde that may be released by other renovation materials, meeting the needs of high-end domestic customers. Additionally, SPC flooring has excellent waterproof properties, making it resistant to moisture or water-induced deformation, and is easy to clean and maintain.

Moreover, the installation of SPC flooring is extremely simple, typically using a floating installation system that can be fixed by interlocking or adhesive, significantly saving installation time and costs. The diverse designs also cater to different customers' personalized needs, allowing for customization based on customer requirements, whether it be wood grain, stone grain, or other patterns.

national customer service hotline:

+86-18934373051

Website:en.liblun.com

E-mail:liblun@163.com

Address: No.18, Luoxia East Road, Danzao Town, Nanhai District, Foshan City

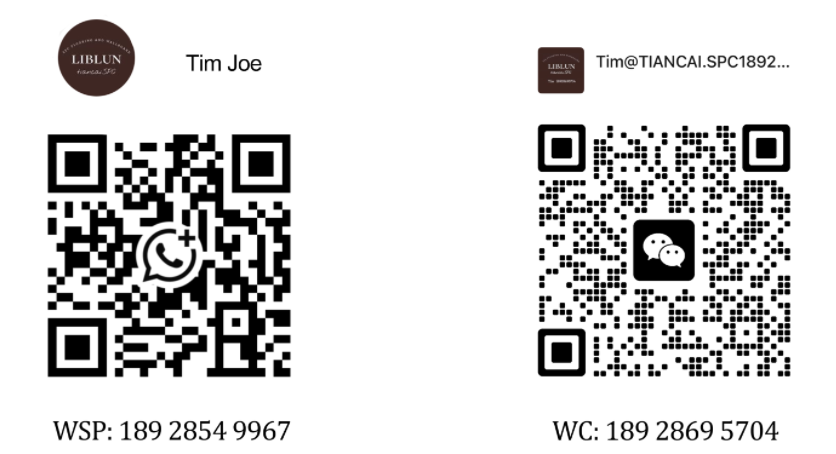

SPC Flooring. QR code

Copyright©Foshan Tiancai Environmental Protection Building Materials Technology Co., Ltd.