News

20

2024

-

11

Discussion on SPC Process Optimization and Management Practices

Author:

Discussion on SPC Process Optimization and Management Practices

In today's highly competitive market environment, companies must continuously pursue process optimization and management efficiency to maintain a sustainable competitive advantage. Statistical Process Control (SPC) has been widely applied in various fields such as manufacturing and services as an effective quality control method. This article will delve into the optimization and management practices of SPC processes, aiming to provide companies with a feasible operational guide to help them achieve higher production efficiency and product quality.

1. Basic Principles and Importance of SPC

SPC is a process control method based on statistical principles, which analyzes data collected during the production process to determine whether the process is in a controlled state and to predict future trends. Its core lies in using tools such as control charts to timely identify abnormal fluctuations in the production process, allowing for adjustments to avoid the production of defective products. The importance of SPC is that it can not only improve product quality but also reduce waste and enhance production efficiency, bringing significant economic benefits to companies.

2. Key Elements of SPC Process Optimization

1. Data Collection and Analysis

Data is the foundation of SPC, and accurate and comprehensive data collection is the first step in optimizing processes. Companies should establish a complete data collection system to ensure the timeliness and accuracy of the data. At the same time, advanced statistical analysis software should be used to deeply mine the data and identify potential improvement points.

2. Selection and Application of Control Charts

The selection of control charts should be based on the characteristics and needs of the process. Common control charts include mean-range control charts and mean-standard deviation control charts. Companies should choose the most suitable control chart based on actual production conditions and correctly set control limits to ensure timely detection of abnormal fluctuations.

3. Establishment of Abnormal Handling Mechanisms

When control charts indicate that an abnormality has occurred in the process, companies should respond quickly and establish effective abnormal handling mechanisms. This includes confirming the abnormal situation, analyzing the causes, formulating and implementing corrective measures, and subsequent tracking and verification. Through closed-loop management, ensure that the problem is thoroughly resolved.

3. Challenges and Countermeasures in SPC Management Practices

1. Employee Training and Awareness Enhancement

The implementation of SPC requires active participation and cooperation from employees. However, many employees lack sufficient understanding and awareness of SPC, which becomes a major obstacle in the implementation process. Therefore, companies should strengthen employee training, enhance their awareness of the importance of SPC, and teach them how to correctly use tools such as control charts.

2. Handling Process Complexity

As production processes become increasingly complex, the implementation of SPC also faces greater challenges. For multivariable and multi-stage production processes, traditional univariate control charts may not meet the needs. In this case, companies should consider adopting methods such as Multivariate Statistical Process Control (MSPC) to monitor process status more comprehensively.

3. Continuous Improvement and Cultural Development

SPC is not a one-time project but a continuous improvement process. Companies should establish a culture of continuous improvement, encouraging employees to actively participate in quality improvement activities, continuously seeking and eliminating waste and bottlenecks in the production process. At the same time, through regular audits and evaluations, ensure the effective operation and continuous improvement of the SPC system.

4. Conclusion

SPC process optimization and management practices are important means to enhance corporate competitiveness. Through accurate data collection and analysis, reasonable selection and application of control charts, and effective abnormal handling mechanisms, companies can significantly improve product quality and production efficiency. At the same time, in the face of challenges during implementation, companies should ensure the smooth implementation and continuous improvement of the SPC system through employee training, handling complex processes, and building a culture of continuous improvement. Only in this way can companies remain invincible in fierce market competition and achieve sustainable development.

national customer service hotline:

+86-18934373051

Website:en.liblun.com

E-mail:liblun@163.com

Address: No.18, Luoxia East Road, Danzao Town, Nanhai District, Foshan City

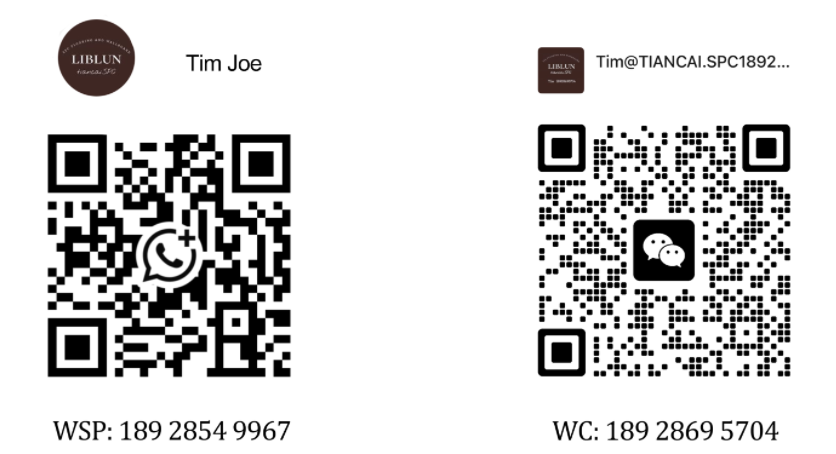

SPC Flooring. QR code

Copyright©Foshan Tiancai Environmental Protection Building Materials Technology Co., Ltd.