News

19

2024

-

11

Wall panel installation guide: from material selection to construction process

Author:

In the family decoration or commercial building renovation, wall panel installation is a common and important work. It is not only related to indoor beauty, but also directly affects the safety of the building, thermal insulation performance and service life. This article will introduce the whole process of wallboard installation in detail, from material selection to construction, to help readers fully understand and smoothly install wallboard.

1. selection

1.1 material selection

There are a wide variety of wallboard materials, common gypsum board, lightweight partition board, solid wood composite board, PVC wallboard, etc. Gypsum board is commonly used in ceiling and indoor partition because of its good fireproof performance and easy processing. Lightweight partition board is suitable for quickly building partition wall due to its characteristics of light weight, high strength, sound insulation and heat insulation. Solid wood composite board is naturally beautiful, but the price is high, and is mostly used for high-grade decoration. PVC wallboard is waterproof and moisture-proof, easy to clean, and suitable for humid environments such as kitchens and bathrooms. The choice needs to be considered according to the specific use scenario, budget and personal preferences.

1.2 quality inspection

When purchasing wallboard, be sure to check whether the product has a certificate of conformity, test report and other documents to ensure that the material meets the relevant national standards. Observe whether the board surface is smooth, no cracks, no degumming, whether the size is standard, and whether the color is uniform. For the wall panels to be spliced, the fit of the spliced parts should also be checked.

2. Preparation

2.1 Measurement and Planning

Before installing the wallboard, the installation area must be accurately measured to determine the size and quantity of the wallboard. According to the spatial layout, plan the arrangement of the wallboard, especially the position of the door and window openings, which should be reserved in advance. At the same time, considering thermal expansion and contraction, appropriate gaps should be reserved between the wall panels.

2.2 tools and materials preparation

According to the installation requirements, prepare necessary tools and materials, such as electric drills, screwdrivers, level rulers, pencils, hammers, expansion plugs, self-tapping screws, caulking agents, etc. Ensure that all tools are complete and functional to improve construction efficiency.

3. Construction

3.1 positioning and marking

Use a level and ruler to mark the installation position of the wall panel on the wall or ground to ensure the levelness and verticality of the wall panel after installation. For the need to install the keel, first according to the design drawings to fix the keel, to ensure that the keel spacing is uniform, stable.

3.2 installation wall panel

According to the installation method of the wall panel (such as dry hanging, gluing, nailing, etc.), take corresponding steps. Taking nailing as an example, first mark the position of the fixing point on the edge of the wall board and the keel, then use an electric drill to pre-punch the wall board, and then use self-tapping screws to fix the wall board on the keel. Be careful not to tighten the screws too tightly to avoid damage to the wall panels. For wall panels that need to be spliced, use caulking agent to fill the gaps to ensure the overall beauty and flatness.

3.3 Detail Processing

During the installation process, pay special attention to the treatment of the corners and the periphery of the door and window frames to ensure that the wall panels are closely attached to these parts to avoid air leakage and rain leakage. For special shaped wall panels, such as curved, wavy, etc., need to be customized in advance or cut with special tools to ensure the installation effect.

3.4 Final Work

After the wall panel is installed, fill all gaps with caulking agent or putty powder, and polish the surface to make the surface flat and smooth. Finally, according to the decoration style, choose the appropriate paint or wallpaper for decoration, complete the overall beautification.

4. acceptance and maintenance

4.1 Acceptance Criteria

After the installation of the wallboard is completed, acceptance is required to check whether the wallboard is flat, without damage, without dislocation, whether the gap is uniform and beautiful, and whether the connection with the surrounding structure is firm. At the same time, use a level and a ruler to check the levelness and verticality of the wallboard to ensure that it meets the design requirements.

4.2 Routine Maintenance

After the wallboard is installed, clean and maintain it regularly to avoid scratching hard objects and prevent water from soaking for a long time. For wall panels that are susceptible to moisture (such as PVC wall panels), more attention should be paid to ventilation and drying to extend the service life.

national customer service hotline:

+86-18934373051

Website:en.liblun.com

E-mail:liblun@163.com

Address: No.18, Luoxia East Road, Danzao Town, Nanhai District, Foshan City

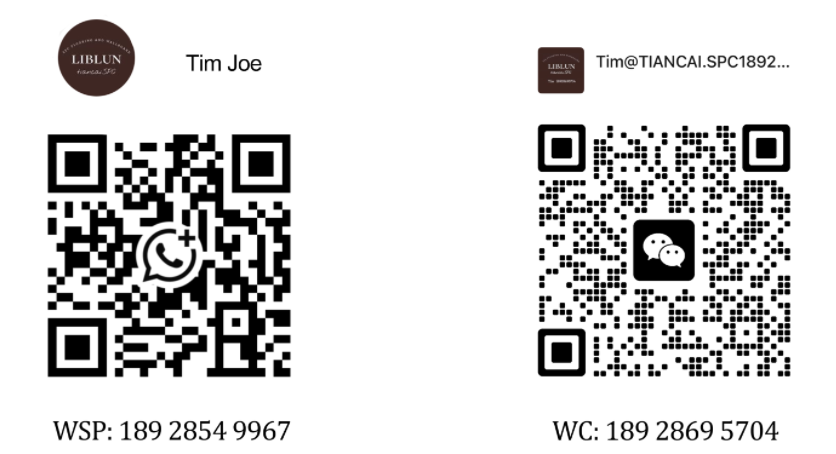

SPC Flooring. QR code

Copyright©Foshan Tiancai Environmental Protection Building Materials Technology Co., Ltd.